Pyrolysis in the Mining Industry

Pyrolysis in the mining industry can solve many problems frequently encountered regarding waste and contamination of the environment.

By Suzanne E. Allaire, PhD

Owner, GECA Environnement

Pyrolysis is the thermo-transformation of matter containing carbon between about 400 and 900°C.

Pyrolysis can transform a whole range of residues into valuable products as solid, liquid, gas, and energy. The mining industry generates various types of residues such as off the road tires (OTR tyres), plastic and food residues of employees living at the mining site, trees and organic matter from deforestation, used oil, tailings, contaminated soil, and so on. Pyrolysis can be a solution to treat and transform all these residues.

Food waste

Food waste and packaging generated by mining villages are usually sent overseas or landfilled. Both activities are expensive and polluting. The organic wastes, when transformed through pyrolysis, can create a char or a biochar that could be used in potting soil to grow plants for food, while the wood vinegar could be used as a plant growth promoting agent. The product of plastic pyrolysis is a highly energetic oil, which can consequently be used on site for heating, making electricity and more. Otherwise, we can extract chemicals to be sold on different markets.

Used OTR tyres

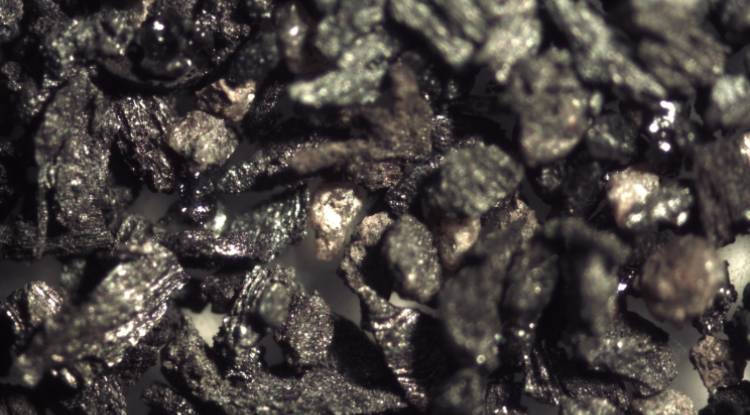

OTR tyres in the mining industry are usually very large because of the type of truck and equipment found on site. The mining industry has the tendency to bury them and uses them for retaining walls. This usage pollutes the soils and the surrounding environment. The mining industry usually generates way more used tyres than they can utilize. Pyrolysis of OTR tyres can create large amount of carbon black, used in the rubber and tyre industry, generates oil and gas for energy, as well as iron, that is easily recycled. Recycling OTR tyres through pyrolysis thus creates renewable products and no wastes.

Tailings and soils contaminated with organics components

Organics contaminants can be found in tailings and soils for several reasons. Oil extraction from oil sand does not completely extract the oil. These sands are near the surface and the oil could easily move toward surface and ground water. The oil is extracted with pyrolysis into the vapour phase, which is then condensed back into oil, leaving the soil clean from oil. This new extracted oil can subsequently be used for various oil applications. Similarly, soils contaminated by car and truck fuel and oil (ex: for engine, lubrication) can also be cleaned the same way. The process is fast and efficient. Thus, pyrolysis recovers oil from sand and soil and decontaminates them to the point that they are comparable to virgin soils, unless the contaminants contain heavy metals.

Use of the pyrolytic products

The pyrolytic gases generated by the mining activities can be used on site to generate heat or energy. The pyrolytic oil can also serve both purposes, on top of others such as for cars and trucks once it is treated. We can extract wood vinegar from pyrolytic oil (when the feedstock is an organic matter) and other chemicals from it. Wood vinegar supports plant growth, serves as an antifungal, a wood preservative for on site buildings, it can treat wounds, and a lot more. The char and biochar have their own markets at interesting prices or can be used on site for plant growth, land reclamation, water treatment, effluent treatment, heavy metal extraction, and more.

Because of the potential for recycling and reuse, on site pyrolysis offers great opportunities to save money and decrease environmental impacts of various mining activities.